熱搜關(guān)鍵詞:

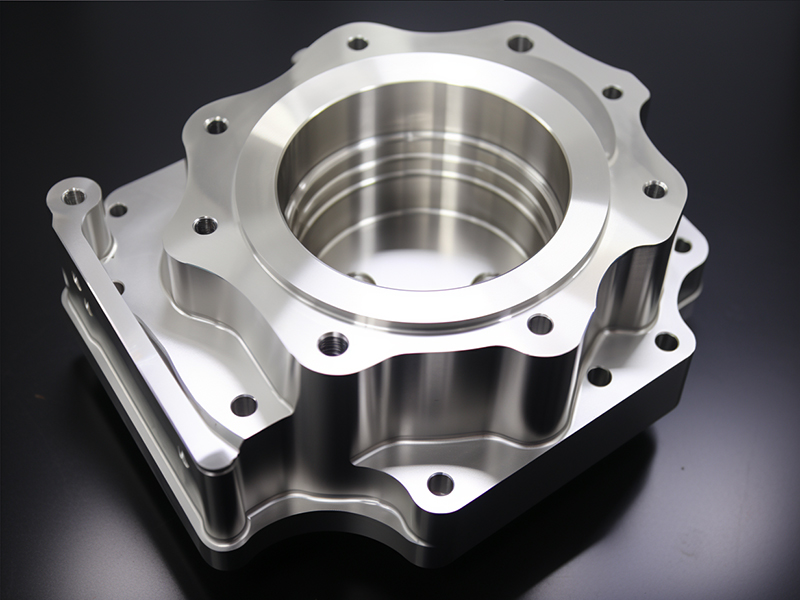

Precision and quality are paramount in the production of CNC-machined aluminum parts. Achieving superior quality requires adherence to rigorous quality management practices throughout the manufacturing process. This article delves into the comprehensive strategies employed by CNC manufacturers to ensure top-notch quality in aluminum component production.

CNC machining of aluminum parts leverages advanced technologies to achieve precision and consistency. Computer-controlled machines execute intricate designs with unparalleled accuracy. High-speed milling and turning processes remove material with efficiency, ensuring the desired specifications are met. This technology-driven approach minimizes errors and enhances the overall quality of the finished parts.

Quality control begins at the design stage and extends through every step of production. CAD/CAM software aids in virtual simulations and precise toolpath generation, optimizing manufacturing processes. During machining, real-time monitoring and measurement systems ensure dimensional accuracy and surface finish. Post-production inspections using coordinate measuring machines (CMM) verify conformity to specifications, guaranteeing each part meets stringent quality standards.

Aluminum alloys are chosen based on mechanical properties, machinability, and application requirements. Material testing, including hardness and composition analysis, validates material integrity. Understanding material behavior under machining conditions is critical to achieving desired outcomes. By selecting the right material and conducting thorough testing, manufacturers enhance product quality and performance.

In conclusion, the meticulous application of quality management practices in CNC aluminum parts manufacturing ensures that each component meets exacting standards. By leveraging advanced technologies, rigorous quality control protocols, and strategic material selection, manufacturers can consistently deliver precision-engineered aluminum parts that exceed customer expectations.

------------------------------------------------------------------------以上內(nèi)容是由深圳捷百瑞科技有限公司資深加工工藝師分享,捷百瑞精密廠家專業(yè)從事精密零件加工、非標(biāo)零件加工、高端產(chǎn)品殼體加工、從定制設(shè)計(jì)到加工落地的機(jī)械加工廠家。公司自2013年成立來,加工的各類高端殼體和高精度零件加工案例達(dá)12000多種,專業(yè)的工程技術(shù)團(tuán)隊(duì)為客戶提優(yōu)質(zhì)的服務(wù),歡迎各界朋友蒞臨我司指導(dǎo)和業(yè)務(wù)洽談!(文章來自http://kiitigaanaskitoolkit.com) 歡迎咨詢!

【本文標(biāo)簽】 cnc精密零件加工廠家 cnc精密加工 鋁件數(shù)控加工 cnc加工工廠

【cnc零件加工】版權(quán)所有

咨詢熱線

13751188387